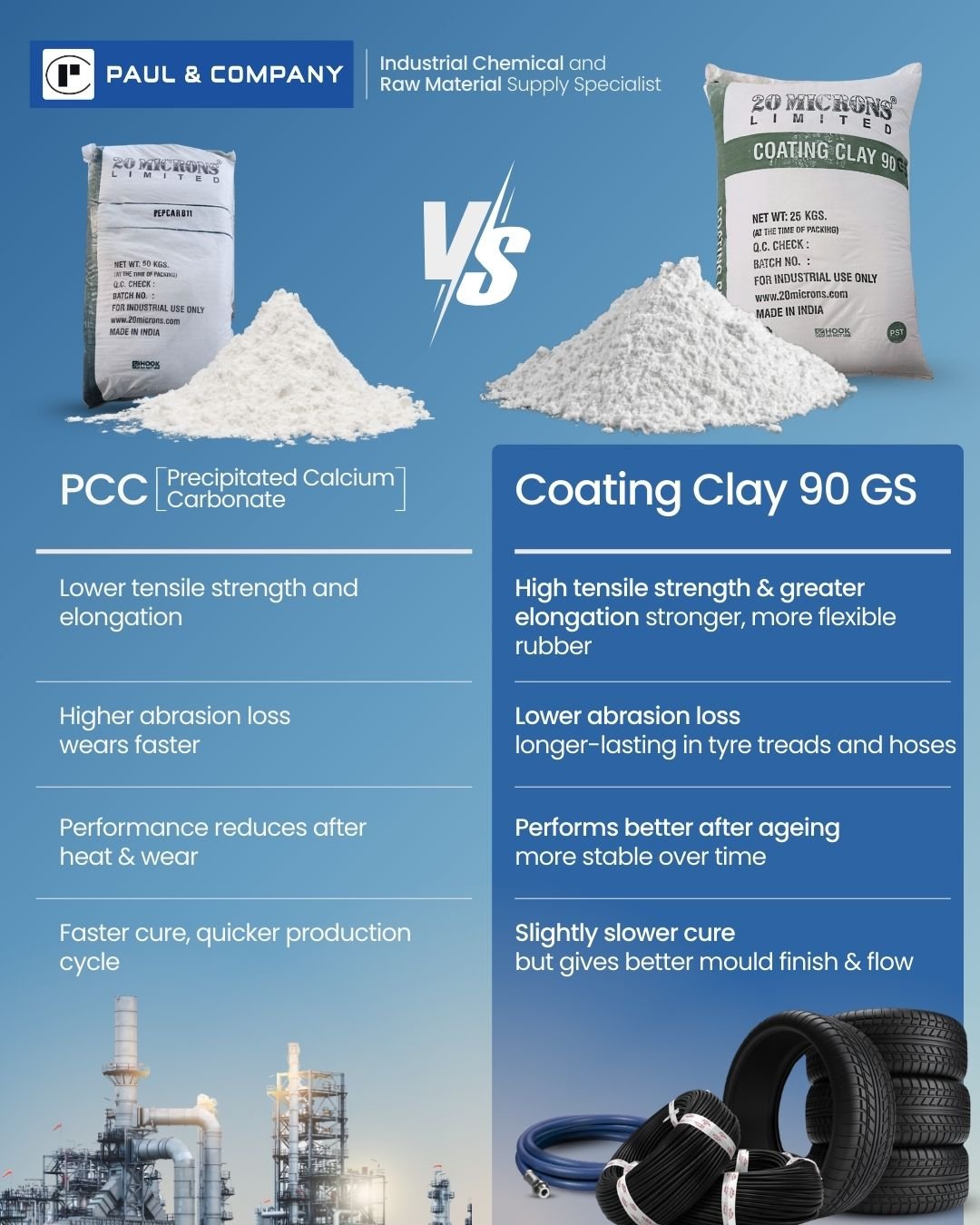

If you’re making tyre tread compounds, industrial wires, or reinforced hoses… your filler choice makes a big difference!

– Cheaper and easy to use

– Works well in basic rubber goods

– Cures faster (less moulding time)

– Good for low to medium performance needs

– Gives stronger rubber with better tensile strength

– More elongation, so rubber bends and stretches better

– Less abrasion, which means longer life in tyre treads

– Performs better even after ageing (heat, wear, time)

– Slightly slower cure, but gives better mould finish

PCC = Cost saver

Clay 90 GS = High strength + durability

Try switching from PCC to Coating Clay 90 GS – your product performance will go up without changing your full recipe!

Get in touch with Paul and Company — trusted industrial chemicals & raw material supply specialists for over 60 years.

India’s trusted name in industrial rubber fillers, since 1960.