From tyres and conveyor belts to hoses and seals, durability and performance are non-negotiable in industrial rubber products.

One key ingredient is quietly making all the difference — Hexamethoxymethylmelamine (HMMM). Let’s break down why it’s a must-have in modern rubber manufacturing.

1.Built-In Bonding Power

Rubber compounds alone can struggle to maintain adhesion with steel cords, textile reinforcements, or inserts — especially under heat, humidity, or mechanical stress.

HMMM solves this by acting as a methylene donor in combination with resorcinol or RF resins, creating a strong, lasting bond between rubber and reinforcements.

2.Performance Under Pressure

When combined with methylene acceptors, HMMM reinforces the compound structure, leading to:

3.Safer & Cleaner Than HMT

HMMM is the modern alternative to Hexamethylenetetramine (HMT) — and for good reason:

It’s why many manufacturers have made the shift from HMT to HMMM.

4.Choose Your Grade, Choose Your Performance

HMMM is available in multiple grades to suit your compound and process needs:

HMMM 50 — Safer handling, softer compounds.

HMMM 65 — Industry’s most adopted — balanced performance and scorch safety.

HMMM 72 — Higher active content for top bonding efficiency.

Liquid grades (≈100% active) are available for precision dosing, zero dust, and superior consistency.

5.Why Source From Paul & Co

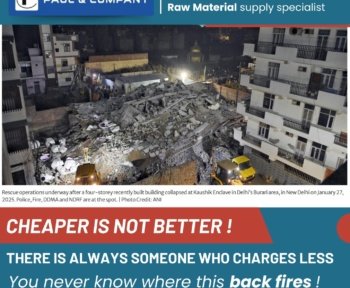

Not all HMMM is the same — purity, active content, and dispersion quality directly impact rubber product performance. Low-grade HMMM can cause:

Paul & Co partners with trusted global suppliers to deliver high-grade HMMM for industrial rubber applications — helping you boost adhesion, extend product life, and improve processing safety.

HMMM isn’t just another additive — it’s an essential crosslinking agent powering the next generation of high-performance rubber products.

Want to know how to integrate the right HMMM grade into your compounding process?

Let’s talk.

India’s trusted name in industrial rubber products, since 1960.